Performance Indicators:

| Physical Properties |

Specification Values |

Test Method |

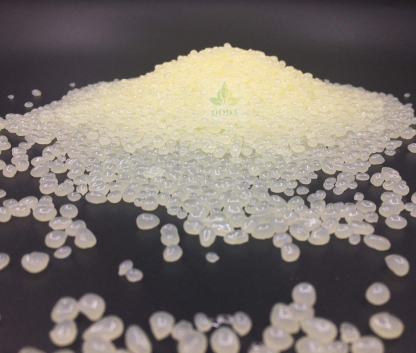

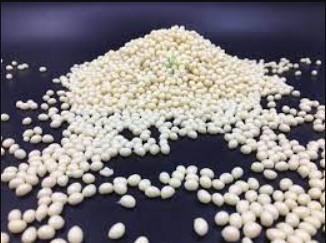

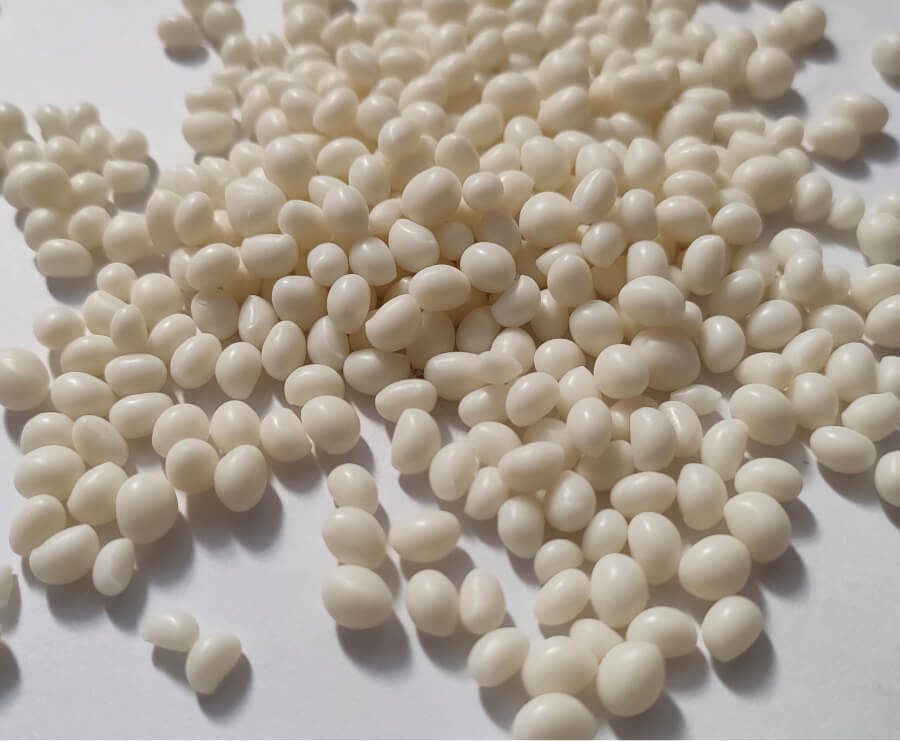

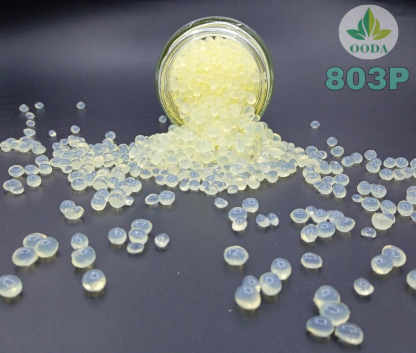

| Appearance |

|

Visual |

| Softening Point |

98℃ ± 5℃ |

Ring and Ball Method |

| Opening Time |

3~50 Seconds |

| Initial Curing Time |

3~4 Seconds |

| Viscosity(180℃) |

2000 ± 500 CPS |

Brookfield 27# |

| Hardness |

70 |

JIS |

| Peel Strength |

12Kg/cm2 |

Ceramic and Other |

| 35Kg/cm2 |

PVC and PVC |

Method of Use:

1Temperature control: The operating temperature is usually controlled between 160 ℃~ 180 ℃, but not exceed 220 ℃. Check the temperature regularly, and use laboratory thermometer , metal thermometer, electrode thermometer directly and systematically. If necessary, readjust it again. Because of long time working,, the thermometer installed on the machine may give the wrong information.

2 Lining speed: 12~15 m/min, according to the width of the edge, low speed can lead to errors.

3 The consumption of hot melt adhesive for sealing side : 300~400g/m2.

Packing and Storage: Paper bags packing, 25Kg/bag. Stored in a cool and dry place, storage period is two years.

Note:

1 Opening and curing time will vary with the temperature at which the adhesive is heated, coating amount, sticking period and the strength.

2 The temperature of the melting system is high, please do not touch it with your hand in order to avoid scald.

3 If the glue drop on the skin, the burnt part should be immediately immersed in cold water for at least 15 minutes and then sent to hospital to be treated.