Performance Indicators:

| Physical Properties |

Specification Values |

Test Method |

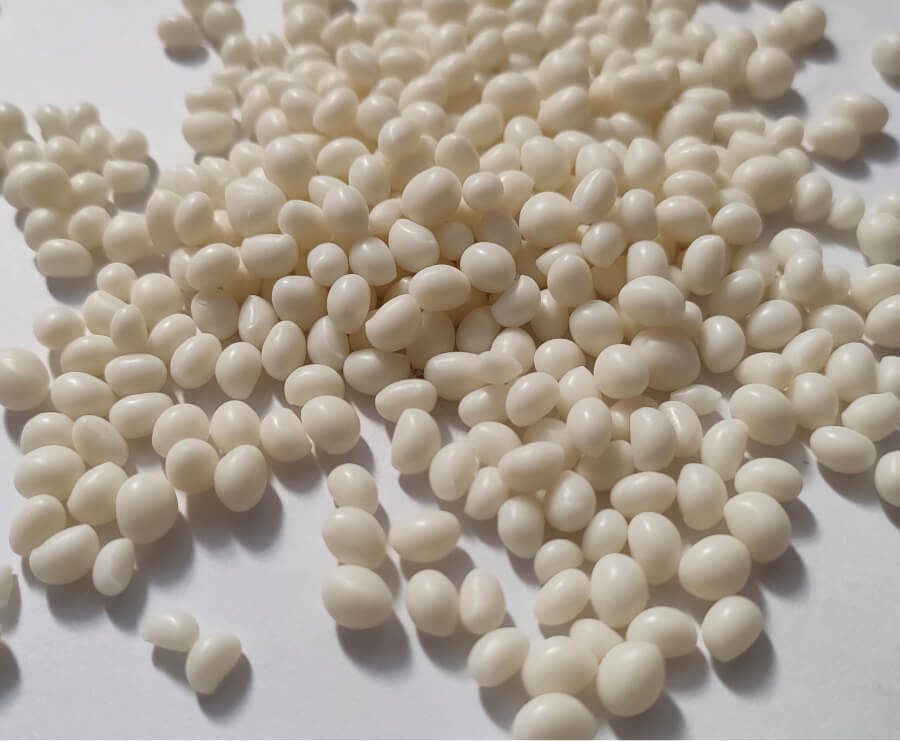

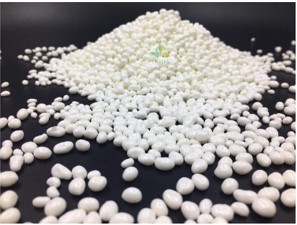

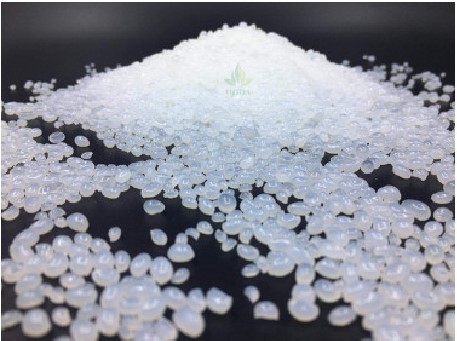

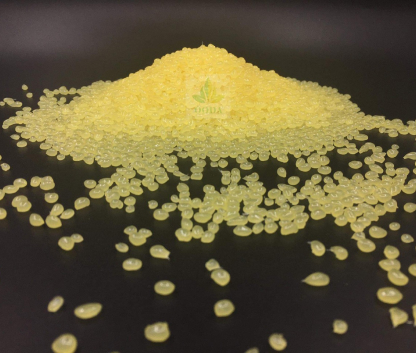

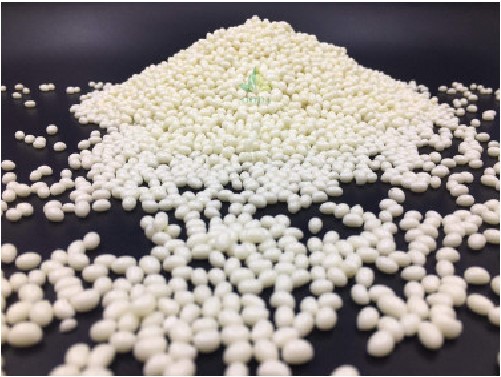

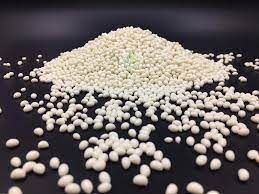

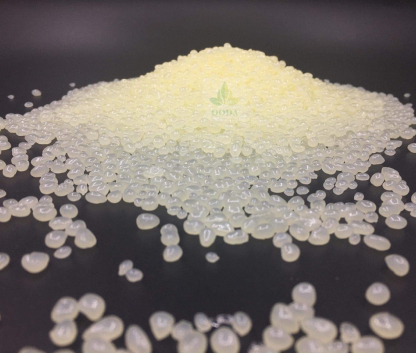

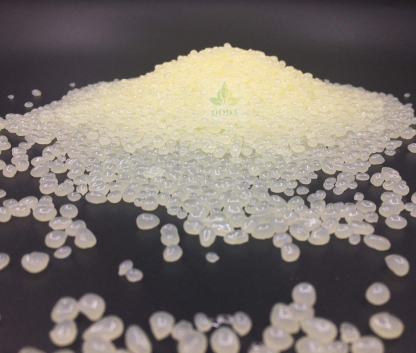

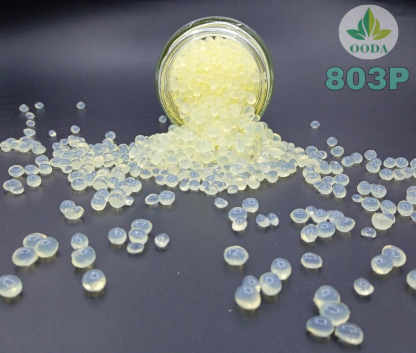

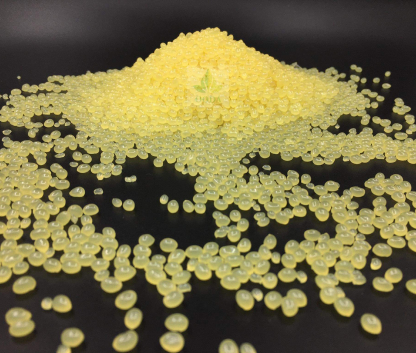

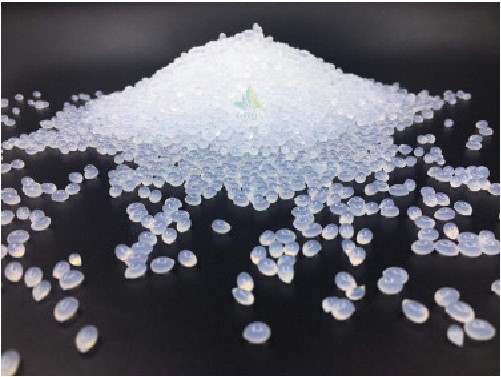

| Appearance |

White Translucent Granular |

Visual |

| Softening Point |

81℃ ± 3℃ |

Ring and Ball Method |

| Opening Time |

3~50 Seconds |

| Initial Curing Time |

15~25 Seconds |

| Viscosity(180℃) |

3500 ± 500 CPS |

Brookfield 27# |

| Hardness |

76 |

JIS |

| Peel Strength |

12Kg/cm2 |

Ceramic and Other |

| 35Kg/cm2 |

PVC and PVC |

Method of Use:

1. Temperature control: The operating temperature is usually controlled between 160 ℃~ 180 ℃, but not exceed 220 ℃. Check the temperature regularly, and use laboratory thermometer , metal thermometer, electrode thermometer directly and systematically. If necessary, readjust it again. Because of long time working,, the thermometer installed on the machine may give the wrong information.

2. Lining speed: 12~15 m/min, according to the width of the edge, low speed can lead to errors.

3. The consumption of hot melt adhesive for sealing side : 300~400g/m2.

Packing and Storage: Paper bags packing, 25Kg/bag. Stored in a cool and dry place, storage period is two years.

Note:

1 Opening and curing time will vary with the temperature at which the adhesive is heated, coating amount, sticking period and the strength.

2 The temperature of the melting system is high, please do not touch it with your hand in order to avoid scald.

3 If the glue drop on the skin, the burnt part should be immediately immersed in cold water for at least 15 minutes and then sent to hospital to be treated.