Viscosity and softening point are two critical properties that define the performance and application behavior of hot melt adhesives. Understanding these characteristics helps manufacturers and users select the right adhesive for specific bonding needs.

🔍 What Is Hot Melt Adhesive?

Hot melt adhesives (HMAs) are thermoplastic materials that are solid at room temperature but become flowable when heated. They are widely used in packaging, woodworking, textiles, and electronics due to their fast-setting time, strong bonding, and versatility.

🧪 Viscosity: Flow Behavior Under Heat

Viscosity refers to the adhesive’s resistance to flow when melted. It determines how easily the adhesive can be applied and how well it wets the surfaces to be bonded.

- Measurement: Typically measured in centipoise (cPs) at a specific temperature, often 350°F (177°C).

- Low viscosity adhesives: Flow easily, ideal for thin substrates or precise application.

- High viscosity adhesives: Thicker and better for gap filling or bonding porous materials.

- Influencing factors:

- Polymer type and concentration

- Additives like tackifiers and plasticizers

- Temperature: viscosity decreases as temperature increases

Maintaining consistent viscosity is crucial for automated dispensing systems and uniform bond strength across production batches.

🔥 Softening Point: Transition to Flow

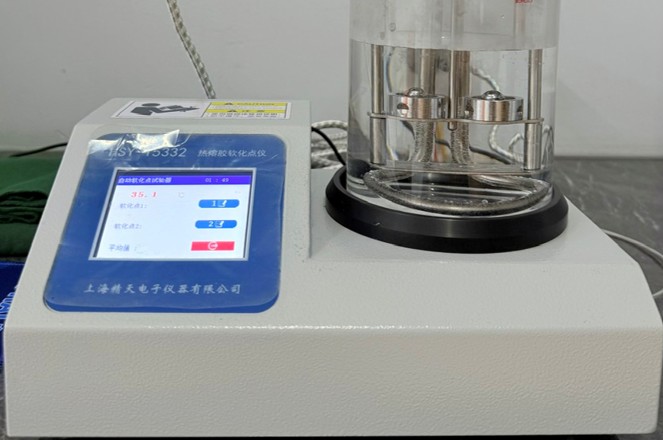

Softening point is the temperature at which the adhesive begins to soften and flow under slight pressure. It’s a key indicator of thermal stability and heat resistance.

- Test method: Most commonly measured using the Ring and Ball method (ASTM D-2398).

- Typical range: 70°C to 120°C depending on formulation.

- Importance:

- Determines the adhesive’s resistance to heat during service

- Helps ensure consistency between production lots

- Not equivalent to heat resistance—actual performance depends on substrate and environmental conditions

Heating rate affects softening point: Faster heating can yield a higher observed softening point, so controlled testing conditions are essential for accuracy.

🧩 Relationship Between Viscosity and Softening Point

While both properties are temperature-dependent, they serve different roles:

|

Property |

Role in Application |

Impact on Performance |

|

Viscosity |

Affects flow and spread ability |

Influences bond uniformity |

|

Softening Point |

Indicates thermal transition |

Determines heat resistance |

A well-formulated hot melt adhesive balances viscosity for ease of application and a softening point that matches the thermal demands of the end-use environment.

🏁 Conclusion

Understanding viscosity and softening point is essential for selecting and using hot melt adhesives effectively. These properties influence everything from application method to long-term durability. Whether you’re sealing cartons or assembling electronics, choosing the right adhesive starts with knowing how it flows and when it softens.